Discover the Versatile Tekkem Slaker for All Your Lime Feed Needs

Clean, Accurate, Simple, Easy to Maintain

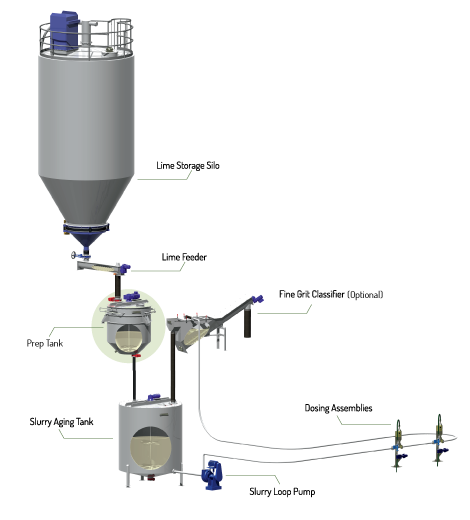

The RDP-Tekkem Slaker’s accuracy is made possible by the load cells ability to precisely add a predetermined amount of lime to a predetermined amount of water so that the chemical reaction of slaking can be performed under optimum conditions. The operating system monitors the temperature of the batch and waits until the maximum temperature has been achieved before the batch is discharged into the Slurry Aging Tank. Our precision dosing utilizes a combination of a pinch valve and a flow meter to accurately dose a predetermined amount of lime from the continuous lime slurry delivery loop. The dosing can be varied at multiple points and also automated to follow plant flow rates.

Download an animated PowerPoint slideshow here and here. Or view them along with other videos below.

Download a complete brochure here.

Discover the Benefits of a High-quality Tekkem Lime Feed Systems and Slaker Solution

The Tekkem Slaker is fully automatic, requiring little or no regular operator attention. The proven RDP-Tekkem operating system takes input from load cells to precisely monitor the water weight and lime weight that are added to make a batch of lime. This information is combined with data from a thermocouple and then used by the program. Changes are made in the lime:water ratio to maintain optimum processing temperatures in the face of changes in the variables which affect the slaking reaction.

– Seasonal changes in process water temperature

– Changes in lime characteristics

– Changes in lime suppliers

65 plants have greatly reduced their maintenance time and cost.

Despite being simple, the mechanical design is rugged and assures years of low maintenance and reliable operation. The RDP-Tekkem Slaker has only one moving part inside the reaction tank which makes maintenance easy and infrequent. There are no bearings or seals located within the tank so the mechanical components are outside of the tank, away from dust and steam. Thus maintenance can be performed from the outside eliminating the need to access the inside of the tank. The RDP-Tekkem Slaker sealed tank contains the dust so the work environment stays clean and safe for personnel.

Lastly, the flexibility is extraordinary. Without any physical changes, the RDP-Tekkem Slaker can switch over and become an accurate hydrated lime feed system, allowing the use of either quicklime or hydrated lime depending on market prices and local preferences.

By using a precise weight control, the slaker is able to properly control the slaking reaction and dilution to an accuracy unmatched by other slakers. The proven RDP-Tekkem Operating System automatically reacts to changes in flow so that treatment conditions are maintained. The entire plant runs more efficiently with the operating system maintaining a steady pH state 24 hours a day.

Since 1960 when T.C Miller first published his award winning work, A Study of the Reaction of Calcium Oxide and Water, It has been known that the lime slaking reaction operates better when the reaction is run at elevated temperatures between 180°F to 190°F. The RDP-Tekkem Slaker consistently runs within a degree or two of a set point, then is precisely diluted to a usable slurry concentration. The accuracy is maintained in spite of process changes.